The bottom line is a unique combination of features: LSE performance resistance to chemicals, weather and heat and ease of converting.

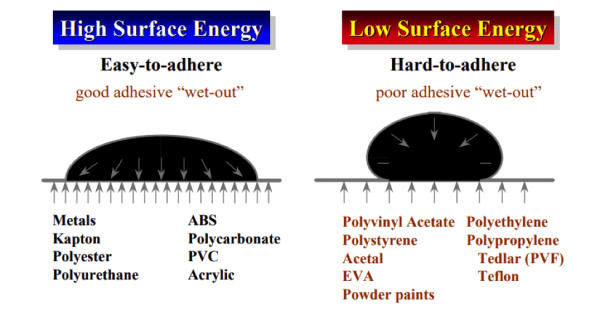

Very low surface energy (LSE) foams, like polyethylene or polypropylene. It also supports efficient converting, with minimal oozing, effective for producing small die-cut parts at faster processing speed. Like every other material, foams have a surface energy, which affects adhesion. Polyethylene is compatible with all Loctite brand adhesives, sealants, primers. Our proprietary solution: High Performance AcrylicĪvery Dennison offers a proprietary, High Performance Acrylic (HPA™) adhesive polymer technology that addresses these issues.Įngineered for use with LSE plastics, it delivers superior initial tack and long-term adhesion and holding power, even under high temperature and harsh environmental conditions. surface treatments were evaluated for the updated strength tables. Rubber-based adhesives may bond well with LSE plastics, but have poor resistance to temperature, weather and chemicals. Acrylics specially engineered for use with LSE plastics are often difficult to be converted. Surface tension of a crystalline polymer, high density polyethylene (HDPE), in supercritical nitrogen under various temperatures and pressures. Standard acrylics provide a balance of adhesion and performance properties for many applications, but generally do not bond well to LSE plastics. The following techniques are typically used as practices for good. Their composition and surface inhibits the “wetting out” necessary to form a stable, lasting bond with most adhesives. Low surface energy plastics, or LSE plastics, are often known by their initials and include such materials as polypropylene (PP), polyethylene (PE or HDPE). Surface preparation plays a key role in ensuring that good bond strength is achieved. from publication: Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite.

HDPE SURFACE ENERGY DOWNLOAD

These plastics, however, present a challenge to adhesive bonding. Download scientific diagram Contact angle and surface energy of HDPE/birch composites. When a droplet of water is placed on a surface, it will bead up to some extent. Most commonly, surface energy is measured with water. Typically, it is measured in a unit called dynes where 1 dyne/cm is equal to 1 mJ/m.

0 kommentar(er)

0 kommentar(er)